Reliable Brass Components for Power Transformers

At Star Freight & Trading FZC LLC, we offer high-quality brass components specifically designed for use in power and distribution transformers. These precision-engineered parts play a vital role in maintaining strong electrical conductivity, mechanical strength, and corrosion resistance in transformer systems.

Our brass components are used in a wide range of transformer applications, including terminal connectors, nuts, bolts, studs, washers, grounding parts, bushings hardware, and other fittings. They ensure long-lasting, vibration-resistant connections and withstand high voltage and temperature variations—making them essential for the reliability and longevity of transformers.

Key Features:

-

Manufactured from high-conductivity, corrosion-resistant brass

-

Available in custom sizes and finishes based on transformer specifications

-

Designed for high voltage and heavy-duty applications

-

Complies with international safety and quality standards

-

Suitable for power transformers, distribution transformers, and switchgear

Whether you’re replacing worn-out hardware or sourcing parts for new builds, our brass components deliver exceptional performance in harsh operational environments.

At Star Freight & Trading FZC LLC, we help industries across the UAE maintain transformer reliability and electrical safety through trusted spare part solutions. Our team ensures timely delivery and technical support for every order.

Frequently Ask Questions

1. What are the components used in transformers?

Transformers consist of several key components, including the core (made of laminated sheets of electrical steel), windings (copper or aluminum wire), insulating oil (for cooling and insulation), bushings (for electrical connection), tap changer (for adjusting voltage), and tank (housing for oil and internal components).

2. What material is used for transformers?

The primary materials used in transformers include copper or aluminum for the windings (due to their conductivity), silicon steel for the core (for magnetic flux), insulating oil (for cooling and electrical insulation), and steel or aluminum for the tank (for housing and protecting internal parts).

3. What are the elements used in transformers?

Transformers mainly use copper or aluminum for conductors, silicon (iron) for the core, oil (mineral or synthetic) for insulation and cooling, and steel for the tank. Additional elements include silica gel in breathers and rubber or plastic in bushings and seals.

4. What are the 10 parts of a transformer?

The 10 key parts of a transformer include:

-

Core (magnetic path)

-

Windings (primary and secondary coils)

-

Insulating oil (for cooling and electrical insulation)

-

Tank (housing for the transformer)

-

Bushing (for electrical connections)

-

Tap changer (for voltage adjustment)

-

Breather (to remove moisture from the air)

-

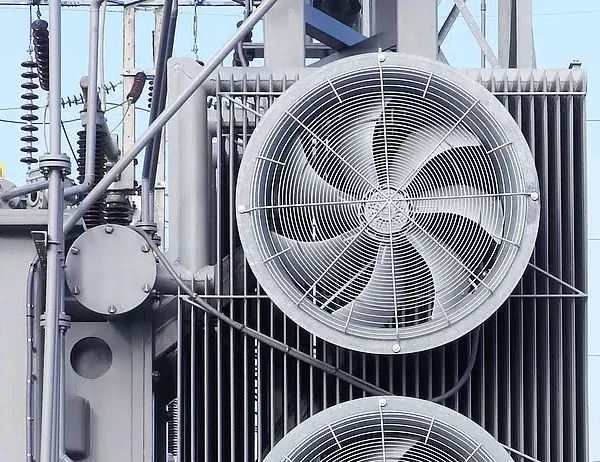

Radiators (for heat dissipation)

-

Oil filter (to purify insulating oil)

-

Buchholz relay (for detecting faults in oil-filled transformers)

5. What are 4 types of transformers?

The four main types of transformers are:

-

Power Transformer (used in high voltage transmission)

-

Distribution Transformer (used to step down voltage for residential or commercial use)

-

Instrument Transformer (used for measurement purposes, like CT and PT)

-

Autotransformer (a type of transformer with a single winding for both primary and secondary circuits)

6. Why is Buchholz Relay used?

The Buchholz Relay is used in oil-filled transformers to detect faults like gas accumulation, overheating, or oil movement. It provides early warning of transformer faults such as internal short circuits or insulation failure, helping prevent severe damage to the transformer.

Reviews

There are no reviews yet.